Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

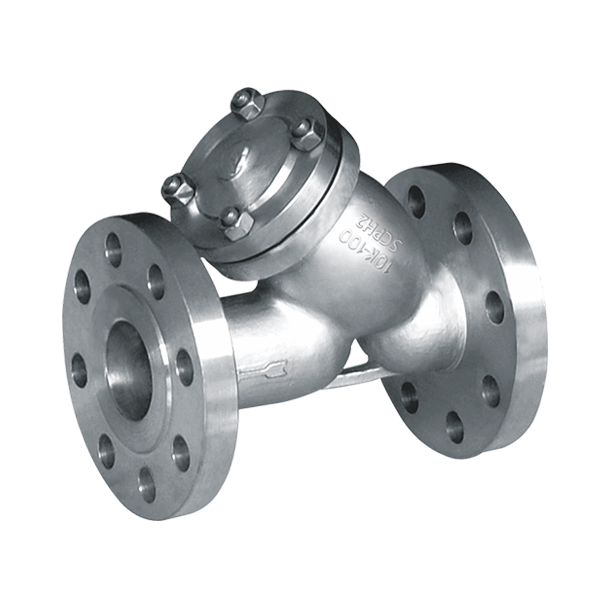

150LB BASKET STRAINER

The basket filter is a type of sand filter that uses a cylindrical cartridge of synthetic fibers as filter medium. This filter can be installed on the edge of the water tank, or under the water tank. The material used for the basket filter is usually called "polyester felt", which is made from natural, recyclable plastic fibers that are woven together to form a felt-like material with high permeability and high resistance to chemicals. This material is then cut into different shapes and sizes, depending on whether it is used as an adhesive layer in a filter, or as filter media itself.

Product introduction:

The basket filter is mounted on a support frame suitable for placing on the edge of the water tank. They can be installed under the water tank or on one side. The filter material of basket filter is the same as that of sand filter, but it is cylindrical rather than flat, and a small amount of surface area is used to provide filtration. Some use adhesive pads or synthetic fibers as filter media; Some use a large amount of carbon crushed stone at the top of the filter to complete chemical filtration (carbon adsorption or chemical precipitation). The principle difference between these types is that the type of organic medium used in the scrubber has a partial pressure gradient of dissolved oxygen on the absorption surface (that is, the gas exists in equilibrium with its liquid or solid phase), while other types (such as wound sponge) need not restrict the gas flow between layers.

Basket filter is a fine filter medium designed to remove the turbidity of liquid. It is usually used in sewage treatment plants, as a primary or secondary clarifier, or for post-treatment of water streams. The idea behind the basket filter is that the water flows through all the baskets between the grids. In addition to the filtering function, it also gives mechanical effect. Basket filters are a suitable addition to any kitchen. The product has stainless steel structure, which can prevent rust and corrosion. It also includes an ergonomic handle that allows you to easily move the filter. The stainless steel construction of this filter is durable and easy to clean, so it won't take up much of your day.

Product advantages:

Basket filters are used to accurately filter and separate particle sizes ranging from 1 to 300 microns. It has the following advantages. High efficiency, long service life and energy saving; Good sealing performance, easy to disassemble and clean; With a rotating handle, 360 ° rotation direction, comfortable operation.

The unique structure of the filter consists of stainless steel and mesh, ensuring excellent filtration performance. The sturdy basket design makes the filter element easy to disassemble and has high durability. Due to its large internal volume (1.52g) and small flow resistance, the filter is suitable for selectively separating small particles from liquid.

Basket strainer. These basket filters provide a clean and effective way to remove oil, fat and food particles from liquids. These screens are light, nearly unbreakable, easy to use and suitable for almost any application. They are characterized by durable stainless steel mesh, corrosion resistance, easy to clean inner wall, polished inner wall, improved sanitary conditions, non rusting coating shell, corrosion resistance and durability in corrosive environment, and are widely used for hot or cold liquid applications - whether operating below the boiling point or within the temperature range determined by the user's personal preference.

Product design:

Basket filters can remove particles of different sizes. Its flow optimization design produces high throughput while reducing pressure and energy losses. Basket filters are an economical alternative to other cartridge filters, allowing you to achieve higher flow rates with lower pressure and energy requirements.

Continuous operation is achieved because the basket filter can handle solids up to 1/4 inch in diameter. Tight filtration is essential to prevent clogging and seizure, thereby reducing downtime and maintenance requirements. The stainless steel filter screen provides a durable base for the polyester non-woven composite media bag and makes the worn bag easier to replace. Top and bottom flange support plates provide dimensional stability, long-term durability, and ease of installation on wood or into other structures. There is a connecting cap on the front side of each board, which can easily access all internal parts, including the quick connect test port.

OVERVIEW: The Model BSF1 is a high quality stainless steel basket strainer with female thread ends that are rated as Class 150# and suitable for steam, water, oil, or gas where protection from foreign matter in a pipeline is required. The stainless steel body performs exceptionally well in high temperatures, up to 800F in continuous service. It provides high resistance to shock, vibration, piping strains, and fire and freezing hazards. stainless steel strainers are often used in the oil and petrochemical industries.

The BSF1 has many unique features, including inlet/outlet bosses with gauge taps (2" and up), plugged bottom drain and cover vent, cast-in support legs (6" and up), epoxy painted bodies, encapsulated cover gasket, and an optional quick-opening design.

Pressure loss is minimized by providing an over the top flow path and large open area ratio. The straining capacity is a minimum of six times that of the connecting pipe. And with its large body and sizable straining element, this basket strainer has the ability to store large quantities of debris. It also features a machined seat with o-ring that enables fine filtrations down to 40 microns.

Utilizing a modified straining element, drains can be fitted with a Stayflow ball valve to allow for the automatic cleaning or flushing of the straining element while keeping the pipeline in service.